Submerged Arc Welding

10 марта, 2014

10 марта, 2014  Oleg Maloletnikov

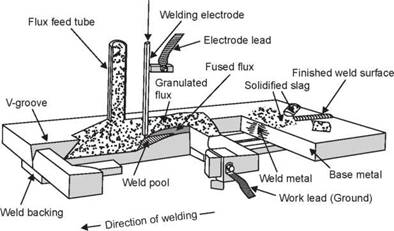

Oleg Maloletnikov Submerged arc welding (SAW) is next to SMAW in importance and in use. The working of the process is shown in Fig. 2.5. In this process the arc and the weld pool are shielded from atmospheric contamination by an envelope of molten flux to protect liquid metal and a layer of unfused granular flux which shields the arc. The flux containing CaO, CaF2 and SiO2 is sintered to form a coarse powder. This flux is then spread over the joint to be made.

• Arc is covered. Radiation heat loss is eliminated and welding fumes are little.

• Process is mechanized or semi-automatic. High currents (200-2000 A) and high deposition rates (27-45 kg/h) result in high savings in cost.

• Power sources of 600-2000 A output, automatic wire feed and tracking systems on mechanized equipment permit high quality welds with minimum of manual skill. Welding speeds up to 80 mm/s on thin gauges and deposition rates up to 45 kg/h on thick sections are major advantages of this process.

|

t |

|

To automatic wire feed

Fig. 2.5 Submerged arc welding process |

• Plate thicknesses up to 25 mm could be welded in a single pass without edge preparation using dcep.

• Process is commonly used for welding all grades of carbon, low alloy and alloy steels.

• Various filler metal-flux combinations may be employed to obtain desired weld deposit characteristics to suit the intended service requirements. Nearly one kg of flux is consumed per kg of filler wire used.

• The process is ideal for flat position welding of thick plates requiring consistent weld quality and high deposition rates.

• Constant voltage dc power supply is self regulating and could be used on constant - speed wire feeder easily. It is, therefore, commonly used power source and is the best choice for high speed welding of thin gauge steels.

Опубликовано в

Опубликовано в