Atomic Hydrogen Welding

23 марта, 2014

23 марта, 2014  Oleg Maloletnikov

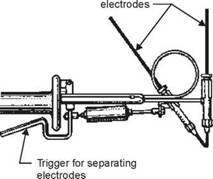

Oleg Maloletnikov In atomic hydrogen welding a single phase AC arc is maintained between two tungsten electrodes and hydrogen gas is introduced into the arc. Hydrogen molecules absorb heat from the arc and change into atomic hydrogen. This atomic hydrogen when comes in contact with the plates to be welded recombines into molecular hydrogen, liberating a large amount of intense heat giving rise to a temperature of 6100°C. Weld filler, metal may be added using welding rod as in oxy-acetylene welding. It differs from SMAW in that the arc is indendent of base metal (work) making electrode holder a mobile without arc getting extinguished. Thus heat input to the weld could be controlled by manually to control weld metal properties. The process has the following special features:

1. High heat concentration.

2. Hydrogen acts as a shield against oxidation.

3. Filler metal of base composition could be used.

4.Most of its applications can be met by MIG process, it is, therefore, not commonly used.

|

Tungsten

Fig. 2.8 Atomic hydrogen welding torch |

|

In the following proceses, ohmic resistance is used as a heat source. |

Опубликовано в

Опубликовано в