Solid-state Welding Power Sources

27 апреля, 2014

27 апреля, 2014  Oleg Maloletnikov

Oleg Maloletnikov • Many modern arc-welding power supply units contain solid-state circuits for regulating the output or replacing the reactors found in conventional systems, or in some cases, as a means of compensating for fluctuations in the mains output voltage. This provides a means of obtaining a stable and consistent operation of the arc in GMA Welding.

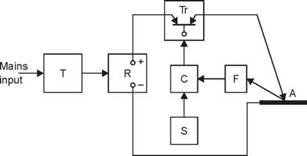

• One such circuit shown in Fig. 3.15 uses transistors introduced between the output from flat characteristics power-supply and the electrode with a feed back system for regulating welding parameters. These transistors can be made to behave as variable resistance in response to command signals. Thus the same supply unit can be made to work as a constant voltage source for GMA welding and then, simply by changing the command signals, it can be made to give a drooping characteristics output to suit GTA Welding.

|

|

Elements of a transistorised power-supply unit to give either a drooping characteristic or a constant-potential output

T—transformer R—rectifier Tr—transistor regulator A—arc F—feedback voltage and/ or current from arc S—reference setting C—command unit (compares signals from F and S ; amplifiers error to give command signal for Tr)

Fig. 3.15 Transisterised power supply unit

• It is possible to design a system in which the voltage and current can be varied during welding according to a predetermined program. For example in welding a small diameter pipe, the heat builds up in the joint and the welder has to progressively increase his speed in order to maintain consistent weld pool size. A transistorised power-supply could be programmed to deliver steadily reducing current as the welder moves round the pipe joint.

• In both GTA and GMA welding pulsed current supplies could be used (as will be discussed later in this chapter). A transistorised power-unit provides accurately controlled current pulses. These power units offer the prospect of providing easily controlled universal power-supply units.

Опубликовано в

Опубликовано в