History of SiC LEDs

25 февраля, 2014

25 февраля, 2014  admin

admin Starting early in the twentieth century, light emission from a solid-state material, caused by an electrical power source, has been reported: a phenomenon termed electroluminescence. Because electroluminescence can occur at room temperature, it is fundamentally different from incandescence (or heat glow), which is the visible electromagnetic radiation emitted by a material heated to high temperatures, typically >750 °C.

In 1891 Eugene G. Acheson established a commercial process for a new manmade material, silicon carbide (SiC), that he termed “carborundum”. The synthesis process was accomplished in an electrically heated high-temperature furnace in which glass (silicon dioxide, SiO2) and coal (carbon, C) reacted to form SiC according to the chemical reaction (Filsinger and Bourrie, 1990; Jacobson et al, 1992)

SiO2 (gas) + C (solid) ^ SiO (gas) + CO (gas)

SiO (gas) + 2C (solid) ^ SiC (solid) + CO (gas) .

Just like III-V semiconductors, SiC does not occur naturally. SiC, which has the same crystal symmetry as diamond, has a very high hardness. On the Mohs Hardness Scale, carborundum has a hardness of 9.0, pure SiC a hardness of 9.2-9.5, and diamond a hardness of 10.0. Because of its high hardness and because it could be synthesized in large quantities at low cost, carborundum was a material of choice for the abrasives industry.

In 1907, Henry Joseph Round (1881-1966) checked such SiC crystals for possible use as rectifying solid-state detectors, then called “crystal detectors”. Such crystal detectors could be used for the demodulation of radio-frequency signals in early crystal-detector radios. Crystal detectors had been first demonstrated in 1906. Crystal-metal-point-contact structures were frequently tested during these times as a possible alternative to expensive and power-hungry vacuum-tube diodes, which were first demonstrated in 1904 (vacuum-tube diode or “Fleming

valve”).

Round noticed that light was emitted from a SiC crystallite as used for sandpaper abrasive. The first light-emitting diode (LED) had been born. At that time, the material properties were poorly controlled, and the emission process was not well understood. Nevertheless, he immediately reported his observations to the editors of the journal Electrical World. This publication is shown in Fig. 1.1 (Round, 1907).

A Note on Carborundum.

To the Editors of Electrical World:

Sirs :—During an investigation of the unsymmetrical passage of current through a contact of carborundum and other substances a curious phenomenon was. noted. On applying a potential of io volts between two points on a crystal of carborundum, the crystal gave out a yellowish light. Only one or two specimens could be found which gave a bright glow on such a low voltage, but with no volts a large number could be found to glow. In some crystals only edges gave the light and others gave instead of a yellow light green, orange or blue. In all cases tested the glow appears to come from the negative pole, a bright blue-green spark appearing at the positive pole. In a single crystal, if contact is made near the center with the negative pole, and the positive pole is put in contact at any other place, only one section of the crystal will glow and that the same section wherever the positive pole is placed.

There seems to be some connection between the above effect and the e. m.f. produced by a junction of carborundum and another conductor when heated by a direct or alternating current; but the connection may be only secondary as an obvious explanation of the e. m.f. effect is the thermoelectric one. The writer would be glad of references to any published account of an investigation of this or any allied phenomena.

New York, N. Y. H. J. Round.

Fig. 1.1. Publication reporting on a “curious phenomenon”, namely the first observation of electroluminescence from a SiC (carborundum) light-emitting diode. The article indicates that the first LED was a Schottky diode rather than a p-n junction diode (after H. J. Round, Electrical World 49,309,1907).

Round was a radio engineer and a prolific inventor who, by the end of his career, held 117 patents. His first light-emitting devices had rectifying current-voltage characteristics; that is, these first devices were light-emitting diodes or LEDs. The light was produced by touching the SiC crystal with metal electrodes so that a rectifying Schottky contact was formed. Schottky diodes are usually majority carrier devices. However, minority carriers can be created by either minority-carrier injection under strong forward-bias conditions, or avalanche multiplication under reverse-bias conditions.

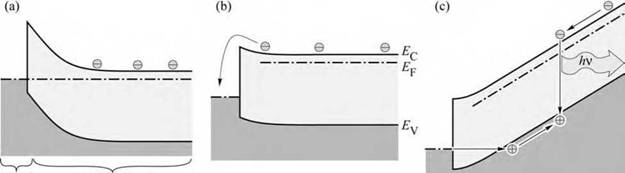

The mechanism of light emission in a forward-biased Schottky diode is shown in Fig. 1.2, which displays the band diagram of a metal-semiconductor junction under (a) equilibrium, (b) moderate forward bias, and (c) strong forward bias conditions. The semiconductor is assumed to be of n-type conductivity. Under strong forward bias conditions, minority carriers are injected

into the semiconductor by tunneling through the surface potential barrier. Light is emitted upon recombination of the minority carriers with the n-type majority carriers. The voltage required for minority carrier injection in Schottky diodes is larger than typical p-n junction LED voltages. Round (1907) reported operating voltages ranging between 10 and 110 V.

|

Metal Semiconductor Fig. 1.2. Band diagram of a Schottky diode under (a) equilibrium conditions, (b) forward bias, and (c) strong forward bias. Under strong forward bias, minority carrier injection occurs, making possible near-bandgap light emission. |

Light can also be generated in a Schottky diode under reverse-bias conditions through the avalanche effect in which high-energy carriers impact-ionize atoms of the semiconductor. In this process, holes are created in the valence band as well as electrons in the conduction band, which will eventually recombine thereby creating light. Additional light-generating processes in Schottky diodes under reverse-bias conditions have been reported by Eastman et al. (1964).

Lossev (1928) reported detailed investigations of the luminescence phenomenon observed with SiC metal-semiconductor rectifiers. The main use of these rectifiers was in solid-state demodulation radio-circuits that did not employ vacuum tubes. Lossev found that luminescence occurred in some diodes when biased in the reverse direction and in some diodes when biased in forward and reverse directions. The author was puzzled about the physical origin of the luminescence. He investigated whether light was generated by heat glow (incandescence) by testing the evaporation rate of a droplet of liquid benzene on the luminous sample surface. He found, however, that the benzene evaporated very slowly and correctly concluded that the luminescence was not caused by incandescence. He postulated that the process by which light was produced is “very similar to cold electronic discharge”. The author also found that the light could be switched on and off very rapidly, making the device suitable for what he called a “light relay”. The pre-1960 history of LEDs was further reviewed by Loebner (1976).

By the late 1960s, SiC films had been prepared by more careful processes (Violin et al., 1969), and p-n junction devices were fabricated, leading to blue light-emitting diodes. Electrical - to-optical power-conversion efficiencies were only 0.005% (Potter et al., 1969). In the ensuing decades, blue SiC LEDs were never substantially improved, because SiC has an indirect bandgap. Although many blue SiC LEDs were actually sold commercially in the early 1990s, they are no longer a viable product. In the end, the best SiC LEDs, emitting blue light at 470 nm, had an efficiency of only 0.03% (Edmond et al., 1993). SiC, the material of the very first LED, could no longer compete with III-V semiconductors.

Опубликовано в

Опубликовано в