Effect of Other Gases on Metal Transfer

6 мая, 2014

6 мая, 2014  Oleg Maloletnikov

Oleg Maloletnikov • Helium, although inert gas, does not produce axial spray transfer. The transfer is globular with both polarities at all current levels.

• Helium arcs are useful, nevertheless, because they provide deep penetration.

• Spray transfer can be obtained by mixing small quantities of Argon (about 20 percent). With helium, the deep penetration is still maintained. Normal commercial mixtures contain 25 percent argon as a safety factor.

• Active gases like carbon-di-oxide and nitrogen do not produce spray transfer, spatter on the other hand is increased.

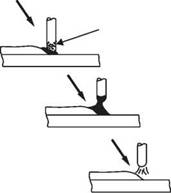

• Spatter can be minimised by burying the arc below the plate surface to trap the spatter in the deep arc crater. This technique is used when:

(a) carbon dioxide is used to shield arcs in mild steel.

(b) nitrogen is used mixed with argon to shield aluminium alloys.

(c) nitrogen is used to shield copper.

• The amount of spatter, massiveness of the drops and instability of transfer generally are greater when electrode is negative.

• Spray transfer can be achieved by painting cesium and sodium on steel wire surface with CO2 shield using direct current electrode negative polarity.

3.8.3 Short Circuiting Transfer (Dip Transfer)

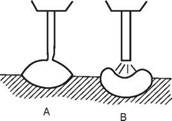

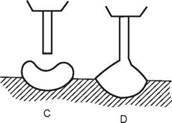

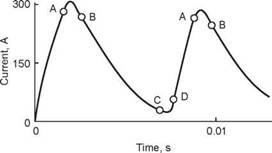

• Metal is tansferred from the electrodes (consumable) to the work through short circuits. It operates at low currents and low voltage (21 V, 200 A or less), the electrode end melts slowly. As the electrode is fed, arc gap shortens, until the tip touches the weld pool (Fig. 3.19 c)

Arc heats weld pool.

Electrode tip is moving towards surface of pool.

|

Arc length gets shorter since current is not high enough to produce rapid melting of electrode. |

|

Direction of welding |

|

End of electrode melts and flows into the weld pool. |

|

Tip of electrode touches the weld pool. Power supply output is short-circuited and the current rises. |

|

Heated region |

|

The arc is re-established and the sequence is repeated. |

|

|

|

The rise in current is controlled so that the end of the electrode is resistance heated. |

|

|

|

|

|

|

Fig. 3.20 (a) Influence of electrode diameter and extension on drop-to-spray transition currents

|

Fig. 3.20 (b) Schematic representation of short circuiting metal transfer |

• The average current is also kept low by using relatively small diameter electrodes.

• With proper equipment adjustment short circuits of the order of hundreds of drops per second are obtained.

• Since little time is available to fuse the electrode, the drops formed are very small, and are transferred to the weld by surface tension when electrode tip and weld pool come in contact.

Опубликовано в

Опубликовано в