ARC WELDING

5 марта, 2014

5 марта, 2014  Oleg Maloletnikov

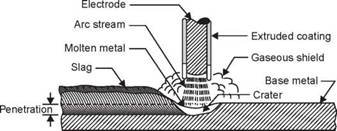

Oleg Maloletnikov An arc is a sustained electric discharge in a conducting medium. Arc temperature depends upon the energy density of the arc column. Arc could be used as a source of heat for welding.

|

Fig. 2.4 Diagrammatic sketch of arc flame |

Arc welding is a group of welding processes that use an electric arc as a source of heat to melt and join metals, pressure or filler metal may or may not be required. These processes include

• Shielded metal arc welding (SMAW)

• Submerged arc Welding (SAW)

• Gas metal arc (GMA, MIG, MAG)

• Gas tungsten arc (GTA, TIG)

• Plasma arc welding (PAW)

• Electroslag/Electrogas Welding

Arc is struck between the workpiece and the electrode and moves relative to the workpiece, manually or mechanically along the joint.

Electrode, may be consumable wire or rod, carries current and sustains the arc between its tip and the work. Non consumable electrodes could be of carbon or tungsten rod. Filler metal is separately supplied, if needed.

The electrode is moved along the joint line manually or mechanically with respect to the workpiece. When a non-consumable elecrode is used, the filler metal, if needed, is supplied by a separate rod or wire of suitable composition to suit the properties desired in the joint. A consumable electrode, however, is designed to conduct the current, sustain the arc discharge, melt by itself to supply the filler metal and melt and burn a flux coating on it (if it is flux

coated). It also produces a shielding atmosphere, to protect the arc and weld pool from the

atmospheric gases and provides a slag covering to protect the hot weld metal from oxidation.

Опубликовано в

Опубликовано в