ARC CHARACTERISTICS

1 мая, 2014

1 мая, 2014  Oleg Maloletnikov

Oleg Maloletnikov 3.7.1 Introduction

• For all practical purposes a welding arc may be regarded as a gaseous conductor which converts electrical energy into heat.

• Arc is a heat source for many welding processes because it produces heat at HIGH INTENSITY. The heat can be easily controlled by controlling the electrical parameters.

• In welding, the arc removes surface oxides and also controls the transfer of metals.

• The welding arcs may be of the following types:

(a) Steady Arc—electrical discharge between two electrodes.

(b) Unsteady Arc—arc interrupted due to electrical short circuiting during metal transfer.

(c) Continuously Non-steady Arc: This is due to alternating directional flow of current.

(d) Pulsed Arc: Intermittent current pulses are superimposed on a regular arc to obtain spray type of metal transfer during the pulse intervals.

3.7.2 The Plasma

• The current is carried by the PLASMA, the ionized state of gas composed of nearly equal number of electrons and ions.

• The electrons flow from negative to positive terminal.

• Other states of matter including molten metal, vapour slags, neutral and excited gaseous atoms and molecules.

• The formation of plasma is governed by the concept of the Ideal Gas Law and Law of Mass Action. A basic equation is given below:

|

...(3.9) |

nent _ 2Zi (2nmeKt)3/2 e V

Z0h3 Kt

where ne, n^ n0 _ particle densities (number per unit volume for electrons, ions and neutral atoms resp.)

Vi _ the ionisation potential t _ temperature in degrees absolute Zi and Z0 _ partition functions for ions and neutral particles. h _ Plank’s constant me _ electron mass K _ Boltzmann’s constant

• The heated gas of the arc attains a temperature of between 5000 and 50,000 K depending upon the kind of gas and intensity of the current carried by it.

• In the region very near to the arc terminals the current-conducting electrons are accelerated so suddenly that the required number of collisions does not occur. Current conduction based wholly on thermal ionization does not hold in this region.

3.7.3 Arc Temperature

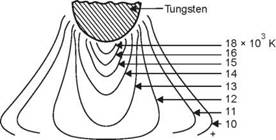

• Arc temperature can be determined by measuring the spectral radiation emitted. The measured values of arc temperatures normally fall between 5000 and 30,000 K, depending upon the nature of plasma and current conducted by it.

• In covered electrodes, due to the presence of easily ionized materials such as sodium and potassium in coatings the maximum temperatures reached are about 6000 K. In pure inert gas arcs the axial temperature may rise to 30,000 K.

|

|

|

200 A - j - 12.1 V 2420 W |

|

5 mm (0.2 in.) |

|

Copper |

|

Fig. 3.17 Isothermal map of an argon-tungsten arc |

• An isothermal map of a 200 A, 12.1 V Argon Arc between tungsten cathode and a watercooled copper anode is shown below.

3.7.4 Radiation Losses

• Radiation loss of energy may be over 20 percent of the total input in the case of argon welding arcs.

• Radiation losses from other gases may be about 10 percent.

3.7.5 Electrical Features

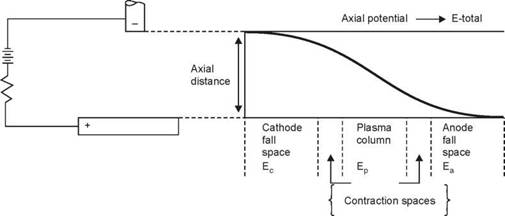

• Every arc offers impedance to the flow of current. The specific impedance is inversely proportional to the density of the charge carriers and their mobility.

• The total impedance also depends upon the radial and axial distribution of the carrier density.

|

Fig. 3.18 Arc potential distribution between electrode and work. |

The current and potential across the cathode fall, Plasma column and Anode Fall regions as shown in Fig. 3.18 are expressed according to

Watts = I (Ea + Ec + Ep) ...(3.10)

where Ea = anode voltage drop Ec = cathode voltage drop Ep = plasma voltage drop.

Опубликовано в

Опубликовано в