Explosive Welding

5 апреля, 2014

5 апреля, 2014  Oleg Maloletnikov

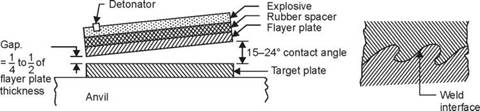

Oleg Maloletnikov Explosive welding is a welding process that uses a controlled application of enormous pressure generated by the detonation of an explosive. This is utilized to accelerate one of the components called the flyer to a high velocity before it collides with the stationary component. At the moment of impact the kinetic energy of the flyer plate is released as a compressive stress wave on the interface of the two plates. The pressure generated is on the order of thousands of megapascals. The surfaces to be joined must be clean. The surface films, if any, are liquefied, scarfed off the colliding surfaces leaving clean oxide free surfaces. This impact permits the normal inter-atomic and intermolecular forces to affect a bond. The result of this process is a cold weld without a HAZ. Combination of dissimilar metals, copper to stainless steel, aluminium to steel or titanium to steel can be easily obtained by this process. EW is well suited to cladding application. The principle of operation is shown in Fig. 2.19.

|

Fig. 2.19 Principle of operation of explosive welding |

The main features of the process are listed below :

1. It joins plates face-to-face.

2. One of the plates called the target plate is kept fixed on anvil. The other plate called the flayer plate is kept at an angle of 15 - 24° to the target plate. The minimum gap

is 4 t° 2 the flayer plate thickness.

3. A layer of explosive charge is kept on the flayer plate with intervening layer of rubber spacers.

4. When explosive charge is detonated the flayer plate comes down and hits the target plate with a high velocity (2400 - 3600 m/s) and the plates get welded face-to-face.

5. The process can be used to join dissimilar materials and the weld interface is seen to be wavy as shown in figure.

6. The various oxides/films present on metal surfaces are broken up or dispersed by the high pressure.

7. Areas from 0.7 to 2 m2 have been bonded by this process.

8. Process is simple, rapid and gives close thickness tolerance.

9. Low melting point and low impact resistance materials cannot be welded by this process effectively.

10. Explosive detonation velocity should be approx 2400 - 3600 m/s. The velocity depends on the thickness of explosive layer and its packing density.

11. Low melting point and low impact resistance materials cannot be welded effectively by this process.

Опубликовано в

Опубликовано в