RESISTANCE WELDING

27 марта, 2014

27 марта, 2014  Oleg Maloletnikov

Oleg Maloletnikov Electroslag Welding

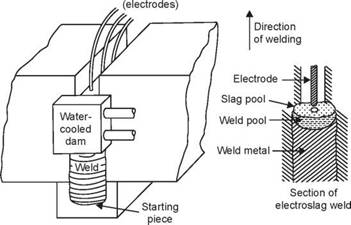

The electroslag welding is used for welding thick plates. The plates have square edge preparation and are set vertically up with about 25 mm gap in between as shown in Fig. 2.9. A starting piece is provided at the bottom. Some flux and welding wire electrodes are fed into the gap between the edges. Arc starts and the slag melts. Molten slag is conductive, the arc is short circuited and heat is generated due to the passage of heavy currents through the slag. The slag agitates vigorously and the parent metal and the filler metal melt, forming a liquid metal pool covered by a layer of liquid slag. This pool is retained by water cooled copper dams. A little flux is added from time to time to maintain a slag pool of constant depth. A number of electrodes could be used depending upon the plate thikness.

|

Filler wires

Fig. 2.9 Electroslag welding set-up |

Power source could be a. c. but d. c. is preferred for alloy steel welding. Welding speed is low and weld pool is large, the cooling rates are, therefore, slow. The microstructure of weld metal and HAZ shows coarse grains. To obtain good impact resistance, carbon and low alloy steels need normalizing treatment.

Slow cooling combined with low hydrogen content of weld metal greatly minimizes the risk of cracking of welds on low alloy steels. As the weld pool is properly protected from atmospheric contamination, the use of deoxidized wire is not essential.

Electroslag welding is used for the vertical welding of plate and sections over 12 mm thick in carbon and low alloy steels and has been used for the welding of high alloy steels and titanium.

2.3.1 Spot Welding

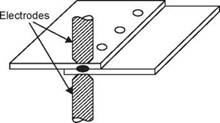

• In this process, the parts to be joined are normally overlapped and the metal at the interface fuses due to resistance heating. The principle of operation of the process is shown in Fig. 2.10. The workpieces are clamped between two water cooled copper electrodes. On the passage of a high transient current the interface melts over a spot and forms a weld. The cooling of the electrode limits the size of the spot. A very high current (10,000 amp or more) is used for a short duration (fraction of a second) to complete the weld. The interfaces to be joined are initially cleaned by various methods: grinding, scratch brushing or vapour degreasing. A spot weld normally contains small porosity (due to shinkage) in the weld center which is usually harmless.

|

Fig. 2.10 Principle of resistance spot welding |

• If a series of spots are to be welded, a higher current is necessary in view of short circuiting provided by the previous weld.

• Cooling of the weld is rapid and steels having more than 0.15% carbon and low alloy steels may require softening of hard structure by passing a second, less intense currect pulse after the welding pulse.

• Electrodes should have high electrical an thermal conductivity and should have resistance to wear. Copper alloys (e. g. Cu— 0.5% Cr, sintered tungsten copper compacts) have been developed which retain hardness even when exposed to welding heat.

• Power source for resistance welding should give a low voltage high current output for steel and nickel alloys to be spot welded. Silver, aluminium, copper and their alloys pose problem in welding due to high electrical and thermal conductivity necessitating high current pulses for short duration.

• Cracking and expulsion of molten metal occurs from excessive welding current and may be avoided by correct adjustment of welding variables.

Опубликовано в

Опубликовано в