Anti-reflection optical coatings

23 марта, 2014

23 марта, 2014  admin

admin Anti-reflection (AR) coatings are frequently used in communication LEDs to reduce the Fresnel reflection at the semiconductor-air interface. For normal incidence, the intensity reflection coefficient for normal incidence is given by

R = n - nair)2 (9.10)

(ns + najr)

where ns and najr are the refractive indices of the semiconductor and of air, respectively.

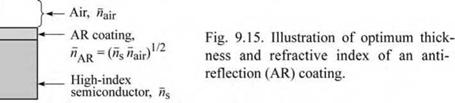

For normal incidence, Fresnel reflection at the semiconductor-air interface can be reduced to zero, if an AR coating cladding the semiconductor has the following parameters:

Thickness: X/4 = X0/(4«ar) Refractive index: nAR = ^nsnair. (9.11)

An AR coating with optimum thickness and refractive index is shown in Fig. 9.15. The refractive indices and the transparency ranges of different dielectric materials suitable for AR coatings are given in Table 9.2.

|

|

|

|ЛУ4 = XQ/ (4/7Ar) І |

|

Table 9.2. Refractive index and transparency range of common dielectrics suitable as anti-reflection coatings (after Palik, 1998).

|

Опубликовано в

Опубликовано в