Steady State Temperature Field

7 июля, 2014

7 июля, 2014  admin

admin The Figures in this section show the state at the rear end of the mesh or flow lines. In the regular mesh next to the filler material, each element has a depth of 2.375 mm in the y - direction.

In the upstream area, there is no change from the initial microstructures, since the incoming material has not been affected by the heat input from this weld pool. For this temperature field, in the downstream area, all the austenite has completely decomposed into its transformation products. It could not be seen at the downstream end. This full decomposition indicates that the microstructure of the material flowing out is essentially stable. Although some of these transformation products are metastable, any changes which occur only do so very slowly unless there is further heating.

|

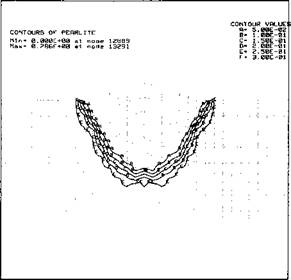

Figure 4-11: Pearlite contours at the ends of streamlines. Contour В is typical of the edge of the HAZ |

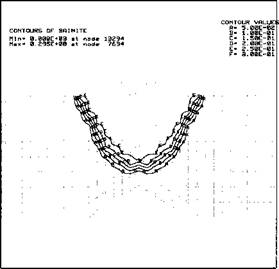

Figures 4-11 and -12 show the isopercentage contours of pearlite and bainite distributions, respectively. After welding, the fraction of ferrite is almost constant at 70%. The major microstructural change is that the formation of bainite reduces the pearlite percentage in the

HAZ. In this weld, the cooling rate behind the weld pool is not large enough to form martensite at the downstream end. The final microstructure outside the HAZ changes little. Inside the HAZ it is mostly ferrite with a mixture of pearlite and bainite. There is about 20-25% bainite adjacent or near the fusion zone, largely due to the increased austenite grain size. Two to three mm within contour E in Figure 4-12, a layer with the largest grain size and the highest bainite is predicted.

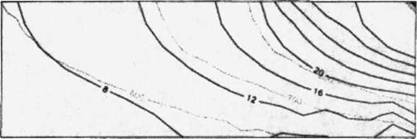

The cooling rate is almost constant for an isothermal contour.

|

Figure 4-12: Bainite contours at the ends of flow lines. The amount of bainite in the FIAZ within contour E is more than 25%. |

|

Flow Line Direction |

|

|

|

Figure 4-13: Overlapping cooling rate and temperature contours (grayed). The range shown is 800-600°C. The corresponding range of cooling rate is 20-8°C/s. Note that for an isothermal contour, e. g. 600°C, the cooling rate at that temperature is nearly constant. |

|

temperature ---------- Cooling Rate ---------- |

The cooling rate is almost constant for an isothermal contour as observed in Figure 4-13.

The cooling rate defined here is AT(°C)/At(s) between two neighboring points along a streamline.

|

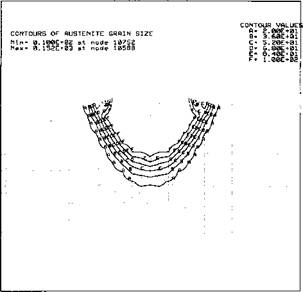

Figure 4-14: The contours of prior austenite grain sizes (|xm) are shown. The grain size in the fusion zone is not shown, since the microstructure model does not apply to the fusion zone. Contours В, C, D, E, and F represent the grain sizes in the HAZ, which are 4-10 times coarser than that in the original base metal. |

Figure 4-14 shows the estimated austenite grain size (jim). The coarse grained HAZ region is next to the fusion zone. The grains in the HAZ are up to 10 times coarser than the original material. Note that the high values inside the fusion zone, or weld metal, may not be correct because this microstructure model does not have the ability to predict them. The HAZ region is likely brittle since the upper bainite is expected to form with large grain size at low cooling rate. If lower bainite is formed at higher cooling rates, the region can have an ideal structure, being hard and tough. However, if the cooling rate was high enough to form martensite the region would likely be very hard, brittle and susceptible to cracking.

Опубликовано в

Опубликовано в