Shielded Metal Arc Welding

6 марта, 2014

6 марта, 2014  Oleg Maloletnikov

Oleg Maloletnikov It is the most commonly used welding process. The principle of the process is shown in Fig. 2.4. It uses a consumable covered electrode consisting of a core wire around which a flux coating containing fluorides, carbonates, oxides, metal alloys and cellulose mixed with silicate binders is extruded.

• This covering provides arc stabilizers, gases to displace air, metal and slag to support, protect and insulate the hot weld metal.

• Electrodes and types of coating used are discussed in more detail in chapter 4. The

electrodes are available in diameters ranging from 2 mm (for thin sheets) to 8 mm

(for use at higher currents to provide high deposition rates). Alloy filler metal compositions could be formulated easily by using metal powders in the flux coating.

• This process has some advantages. With a limited variety of electrodes many welding jobs could be handled. Equipment is simple and low in cost. Power source can be connected to about 10 kW or less primary supply line.

• If portability of the power source is needed a gasoline set could be used. Solid-state, light weight power sources are available which can be manually carried to desired location with ease. It, therefore, finds a wide range of applications in construction, pipe line and maintenance industries.

• The process is best suited for welding plate thicknesses ranging from 3 mm to 19 mm. Greater skill is needed to weld sections less than 3 mm thickness.

• Hard surfacing is another good application of this process.

SMAW is used in current ranges between 50-300 A, allowing weld metal deposition rates between 1-8 kg/h in flat position.

• Normally a welder is able to deposit only 4.5 kg of weld metal per day. This is because usually in all position welding small diameter electrodes are used and a considerable electrode manipulation and cleaning of slag covering after each pass is necessary. This makes the labour cost quite high. Material cost is also more because only 60% of the electrode material is deposited and the rest goes mainly as stub end loss.

• Inspite of these deficiencies, the process is dominant because of its simplicity and versatility. In many situations, however, other more productive welding processes such as submerged arc and C02 processes are replacing SMAW technique.

Brief details regarding electrode flux covering, its purpose and constituents are given

below:

SMA Welding uses a covered electrode core wire around which a mixture of silicate binders and powdered materials (e. g. carbonates, fluorides, oxides, cellulose and metal alloys) is extruded and baked producing a dry, hard concentric covering.

Purpose of covering: 1. stabilizes arc 2. produces gases to shield weld from air, 3. adds alloying elements to the weld and 4. produces slag to protect and support the weld 5. Facilitate overhead/position welding 6. Metallurgical refining of weld deposit, 7. Reduce spatter, 8. Increase deposition efficiency, 9. Influence weld shape and penetration, 10. Reduce cooling rate, 11. Increase weld deposition by adding powdered metal in coating.

Coating constituents:

1. Slag formers: SiO2, MnO2, and FeO. Al2O3 (sometimes).

2. Improving Arc characteristics: Na2O, CaO, MgO and TiO2.

3. Deoxidizers: Graphite, Al and woodflour.

4. Binders: Sodium silicate, K-silicate and asbestus.

5. Alloying elements: to enhance strength: V, Ce, Co, Mo, Al, Zr, Cr, Ni, Mn, W. Contact electrodes have thick coating with high metal powder content, permit DRAG

or CONTACT welding and high deposition rates.

|

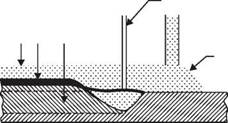

Excessive granular flux |

|

■ Fused flux shield Solidified weld |

|

Fig. 2.5 Submerged arc welding-working principle |

|

|

|

Consumable electrode Flux feed tube Granular flux |

Опубликовано в

Опубликовано в