General characteristics of high-brightness LEDs

29 марта, 2014

29 марта, 2014  admin

admin The improvement in luminous efficiency of visible-spectrum LEDs has been truly breathtaking. The advancement of LED efficiency can be compared to the advancement made in Si integrated circuits where the performance increase versus time has been characterized by “Moore’s law”. This “law” states that the performance of Si integrated circuits doubles approximately every 18 months.

The historical development of the luminous efficiency of visible-spectrum LEDs is shown in Fig. 12.13 (Craford, 1997, 1999). The chart illustrates the modest beginnings of visible-spectrum LED technology which started in the 1960s. If the progress from 1960 to 2000 is assumed to be continuous, then the LED luminous efficiency has doubled every 4 years. The following types of LEDs are shown in the figure.

• GaAsP LEDs grown on GaAs substrates. The GaAsP/GaAs material system is lattice mismatched so that an abundance of misfit dislocations occurs in GaAsP epitaxial films. As a result, these LEDs have a low luminous efficiency (of the order of only 0.1 lm/W). Red GaAsP LEDs are still being manufactured due to the simple epitaxial growth and low fabrication cost.

• GaP LEDs doped with radiative recombination centers. Pure GaP is an indirect semiconductor and therefore has a low radiative efficiency. However, when doped with isoelectronic impurities such as N or co-doped with Zn and O, radiative transitions in the red and green spectral range occur via these centers.

• GaAsP/GaAs LEDs doped with N emitting in the red. Again a mismatched materials system with low efficiency due to the abundance of misfit dislocations.

• AlGaAs/GaAs LEDs emitting in the red. These LEDs employ GaAs quantum well active regions.

• AlGaAs/AlGaAs double heterostructure LEDs emitting in the red using AlGaAs active regions and AlGaAs barriers.

• AlGaInP/GaAs LEDs with absorbing GaAs substrates

• AlGaInP/GaP LEDs and with wafer-bonded transparent GaP substrates.

• Also included in the chart is a result by Krames et al. (1999) who reported LEDs with efficiencies exceeding 100 lm/W using AlGaInP/GaP LEDs with truncated inverted- pyramid-shaped dies.

• GaInN LEDs emitting in the blue and green wavelength range.

Figure 12.13 also shows the luminous efficiency of conventional light sources including Edison’s first light bulb (1.4 lm/W) and red and yellow filtered incandescent lamps. Inspection of the figure reveals that LEDs outperform filtered red and yellow incandescent lights by a large margin.

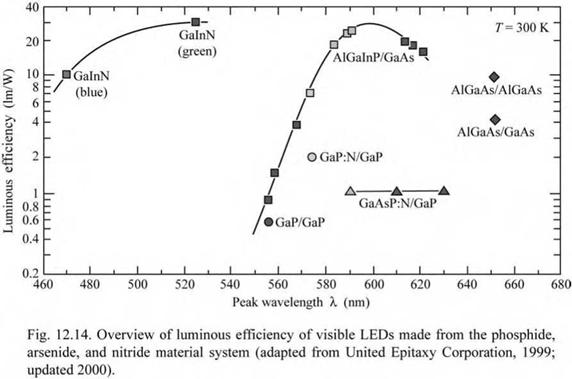

The luminous efficiency of high-brightness LEDs and of some low-cost LEDs is shown versus wavelength in Fig. 12.14 (United Epitaxy Corp., 1999). The figure indicates that yellow (590 nm) and orange (605 nm) AlGaInP and green (525 nm) GaInN LEDs are excellent choices for high luminous efficiency devices.

|

|

The fact that amber (dark yellow or orange-yellow) and orange AlGaInP LEDs provide an excellent luminous efficiency is also due to the high eye sensitivity in this wavelength range. Note that the maximum eye sensitivity occurs in the green at 555 nm, so that a green LED emitting at that wavelength appears brighter than an LED with the same optical power emitting at any other wavelength.

Owing to the high luminous efficiency and the lower manufacturing cost compared with green GaInN LEDs, amber AlGaInP LEDs are used in applications where high brightness and low power consumption are desirable, e. g. in highway signage applications. In the 1980s, such highway signs were made with power-hungry incandescent lamps powered by an electrical generator which, in turn, was powered by a gasoline engine. Today such signs use energy-saving amber LEDs powered by solar cells (during daytime) and batteries (at night).

Figures 12.13 and 12.14 also show low-power and low-cost LEDs such as GaAsP and GaP:N LEDs with much lower luminous efficiency. These LEDs are not suitable for high-brightness applications due to their inherently lower quantum efficiency. The GaAsP LEDs are mismatched to the GaAs substrate and therefore have a low internal efficiency. The GaP:N LEDs also have a low efficiency due to the nitrogen-impurity-assisted nature of the radiative transition.

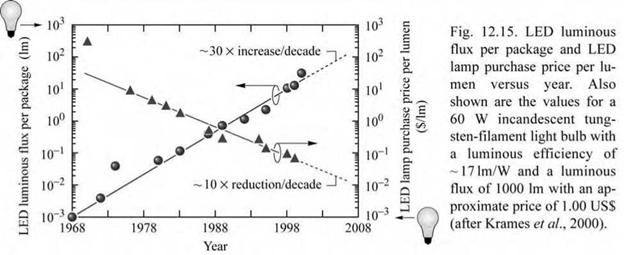

Not only the luminous efficiency but also the total power emitted by an LED is of importance for many applications, in particular for applications where a high luminous flux is required. This is the case, for example, in signage, traffic light, and illumination applications. Whereas conventional light sources such as incandescent light bulbs can be easily scaled up to provide high light power, individual LEDs are low-power devices. The historical development of the luminous flux per LED package, measured in lumens, is shown in Fig. 12.15 (Krames et al., 2000). The figure shows that the luminous flux per LED package has increased by about four orders of magnitude over a period of 30 years.

|

|

For comparison, Fig. 12.15 shows the luminous flux and an approximate purchase price of a 60 W incandescent light bulb with a luminous flux of 1000 lm. The figure illustrates that continued progress in the performance and manufacturing cost of LEDs is required to enable LEDs to enter into the general illumination market. Note that the cost shown in the figure is just the purchase price of the lamp and does not include the cost for the electrical power consumed over the lifetime of the lamp. The cost of the electrical power required to run an incandescent light bulb is much higher than the purchase price of the lamp so that efficient light sources can have a cost advantage over incandescent lights even if the initial purchase price is much higher.

Опубликовано в

Опубликовано в