GAS WELDING

3 марта, 2014

3 марта, 2014  Oleg Maloletnikov

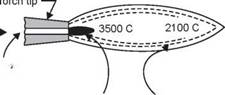

Oleg Maloletnikov Gas welding includes all the processes in which fuel gases are used in combination with oxygen to obtain a gas flame. The commonly used gases are acetylene, natural gas, and hydrogen in combination with oxygen. Oxyhydrogen welding was the first commercially used gas process which gave a maximum temperature of 1980°C at the tip of the flame. The most commonly used gas combination is oxyacetylene process which produces a flame temperature of 3500°C. This process will be discussed in detail in the following paragraphs.

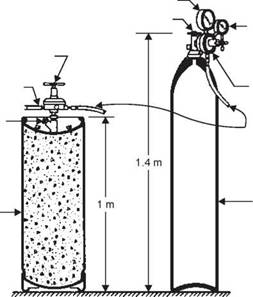

1. Oxyacetylene welding flame uses oxygen and acetylene. Oxygen is commercially made by liquefying air, and separating the oxygen from nitrogen. It is stored in cylinders as

shown in Fig. 2.1 at a pressure of 14 MPa. Acetylene is obtained by dropping lumps of calcium carbide in water contained in an acetylene generator according to the following reaction.

CaC2 + 2H2O = Ca(OH)2 + C2H2 Calcium carbide + Water = Slaked lime + Acetylene gas

|

Tank pressure gage Tank valve |

|

Line pressure gage All fittings on oxygen cylinder have right hand threads |

|

Regulator |

|

To welding torch |

|

Oxygen tank 2 pressure 1550 N/mm (max.) |

|

Fig. 2.1 Cylinders and regulators for oxyacetylene welding [1] |

|

|

|

Acetylene regulator Pressure gages Tank valve |

|

All fittings Acetylene cylinder 2 175 N/mm2 (max.) |

2. Concentrated heat liberated at the inner cone is 35.6% of total heat. Remaining heat develops at the outer envelope and is used for preheating thus reducing thermal gradient and cooling rate improving weld properties.

3. 1 Volume O2 is used to burn 1 Volume of acetylene, in the first reaction. This oxygen

is supplied through the torch, in pure form 1 — Volume of additional oxygen re-

2

quired in the second reaction is supplied from the atmosphere.

4. When oxygen is just enough for the first reaction, the resulting flame is neutral. If less than enough, ^ the flame is said to be reducing flame. If more than enough oxygen is supplied in the first reaction, the flame is called an oxidizing flame.

5. Neutral flame has the widest application.

• Reducing flame is used for the welding of monel metal, nickel and certain alloy steels and many of the non-ferrous, hardsurfacing materials.

• Oxidising flame is used for the welding of brass and bronze.

|

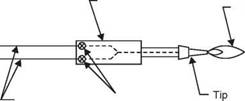

Torch and mixing device |

|

|

|

Flame |

|

Hoses |

|

Manual control valves |

|

|

|

regulators |

|

|

|

1275 C |

|

Inner Luminous cone: 1st reaction |

|

C2H2 + O2 > 2 CO + H2 |

|

Oxyacetylene mixture |

|

Outer envelope (used for pre-heating): 2nd reaction 2CO + O2 = 2CO2 + 570 kJ/mol of acetylene |

|

H2 + - O2 = H2O + 242 kJ/mol |

Total heat liberated by 1st reaction

(227 + 221) = 448 kJ/mol C2H2 Total heat by second reaction = (570 + 242) = 812 kJ/mol of C2H2

Total heat supplied by the combustion = (448 + 812) = 1260 kJ/mol of C2H2

Fig. 2.2 Schematic sketch of oxyacetylene welding torch and gas supply [1].

Advantages:

1. Equipment is cheap and requires little maintenance.

2. Equipment is portable and can be used in field/or in factory.

3. Equipment can be used for cutting as well as welding.

Acetylene is used as a fuel which on reaction with oxygen liberates concentrated heat sufficient to melt steel to produce a fusion weld. Acetylene gas, if kept enclosed, decomposes into carbon and hydrogen. This reaction results into increase in pressure. At 0.2 N/mm2 pressure, the mixture of carbon and hydrogen may cause violent explosion even in the absence of oxygen, when exposed to spark or shock. To counter this problem, acetylene is dissolved in acetone. At 0.1 N/mm2 one volume of acetone dissolves twenty volumes of acetylene. This solubility linearly increases to 300 volumes of acetylene per one volume of acetone, at

1.2 N/mm2.

An excess of oxygen or acetylene is used depending on whether oxidising or reducing (carburizing) flame is needed.

Oxidizing (decarburizing) flame is used for the welding of brass, bronze and copper-zinc and tin alloys, while reducing (carburising) flame is used for the welding of low carbon and alloy steels monel metal and for hard surfacing. Neutral flame is obtained when the ratio of oxygen to acetylene is about 1 : 1 to 1.15 : 1. Most welding is done with neutral flame. The process has the advantage of control over workpiece temperature, good welds can therefore be obtained. Weld and HAZ, being wider in gas welding resulting in considerable distortion. Ineffective shielding of weld-metal may result in contamination. Stabilised methyl acetylene

propadiene (MAPP) is replacing acetylene where portability is important. It also gives higher energy in a given volume.

Опубликовано в

Опубликовано в