Butt (Upset) Welding

30 марта, 2014

30 марта, 2014  Oleg Maloletnikov

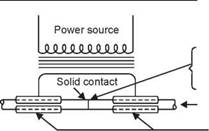

Oleg Maloletnikov The principle of the process is shown in Fig. 2.13. Here the workpiece temperature at the joint is raised by resistance to the passage of an electric current across the interface of the joint. The parts to be joined (wires or rods usually) are held in clamps, one stationary and the other movable which act as conductors for the low voltage electric supply and also apply force to form the joint. Force is applied only after the abutting surfaces reach near to the melting temperature. This causes up-setting. Uniform and accurately mating surfaces are desirable to exclude air and give uniform heating.

|

|

|

Bar stock ■ |

|

Fig. 2.13 Sketch of resistance butt welding |

2.3.4 Percussion Welding

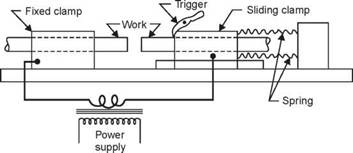

This process makes butt welds at incredible speed, in almost any combination of dissimilar materials and without the flash formation (Fig. 2.14). It relies on arc effect for heating.

|

Fig. 2.14 Principle of percussion welding |

The pieces to be joined are kept apart, one in a stationery holder and the other in a moveable clamp held against a heavy spring pressure. When the movable clamp is released the part to be welded moves towards the other part. Arcing occurs when the gap between the pieces to be welded is 1.6 mm. The ends to be welded are prepared for accurate mating. An extremely heavy current impulse flows for a short duration (0.001 to 0.1 second) across the gap between the pieces forming an arc. The intense heat developed for a very short duration causes superficial melting over the entire end surfaces of the bars. Immediately after this current pulse, the pieces are brought together with an impact blow (hence the name percussion) to complete the weld.

The electric energy for the discharge is built-up in one of two ways. In the electrostatic method, energy is stored in a capacitor, and the parts to be welded are heated by the sudden discharge of a heavy current from the capacitor. The electromagnetic welder uses the energy discharge caused by the collapsing of the magnetic field linking the primary and secondary windings of a transformer or other inductive device. In either case intense arcing is created which is followed by a quick blow to make the weld.

Special Applications:

• Heat treated parts can be joined without affecting the heat treatment.

• Parts having different thermal conductivities and mass can be joined successfully.

For example stellite tips to tool shanks, copper to alluminium or stainless steel. Silver

contact tips to copper, cast iron to steet, zinc to steel. These welds are produced without flash or upset at the joint.

Limitation:

The limitation of the process is that only small areas upto 650 mm2 of nearly regular sections can be welded.

2.3.5 High Frequency Resistance Welding

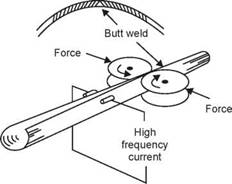

In high frequency resistance welding shown in Fig. 2.15, welding current of 200-450,000 Hz frequency passes between the electrodes in contact with the edges of a strip forming a tube when it passes through forming rolls. The rolls also apply welding pressure. The amount of upset is regulated by the relative position of the welding electrodes and the rolls applying the upset force. The required welding heat is governed by the current passing through the work and the speed of tube movement.

|

Fig. 2.15 Sketch of high frequency resistance welding |

Опубликовано в

Опубликовано в