ARC WELDING POWER SUPPLY EQUIPMENTS

25 апреля, 2014

25 апреля, 2014  Oleg Maloletnikov

Oleg Maloletnikov An arc welding power supply equipment should have the following characteristics:

• must isolate the welding circuit from the mains supply.

• provide the required voltages and desired welding currents for the operation.

• provide the output volt-ampere characteristics which matches the arc system.

• incorporate a low-voltage supply for the operation of auxiliary units.

• if the work is to be carried out on site the unit should be self contained with a petrol or diesel engine driving a generator or alternator.

3.3.1 Alternating-current Welding Power Sources

Alternating current power sources are commonly used in manual metal arc welding of steels and GTA Welding of aluminium and its alloys. For a. c. welding the power supply is invariably a transformer with a control for current adjustment either by varying the inductance or by altering the magnetic coupling between primary and secondary windings of the transformer.

The flow of alternating current in welding circuit is regulated by placing an inductor in line between the transformer and the electrodes. By changing the inductance the current can be changed. For current control during welding a means of changing this inductance is necessary.

Three different types of reactors are available for changing this inductance for current control:

— tapped reactors

— moving core reactors

— saturable reactors

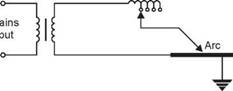

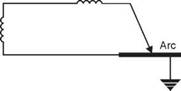

Tapped reactors. These consist of a copper cable wound on a laminated core. The windings are provided with tapping circuit as shown in Fig. 3.7. Coarse and fine controls are provided, but only a limited number of settings can be accomodated.

|

|

|

Transformer |

|

Reactor |

|

M; in| |

|

Fig. 3.7 Tapped reactors |

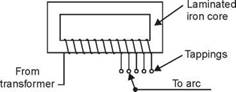

Moving-core reactor. A laminated core is moved in or out of reactor coil, thus increasing or reducing the inductance of the winding. See Fig. 3.8. This system has the advantages of continuously variable adjustment.

|

Transformer Reactor

|

|

From Reactor winding

Fig. 3.8 Moving core reactor |

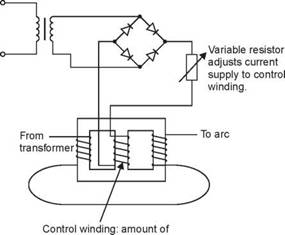

Saturable reactors. Here welding current control is achieved by putting saturable reactor unit in the secondary circuit. See Fig. 3.9. Direct current supplied to this winding affects the impedance offered to alternating current flowing in the main coil. Thus welding current can be continuously regulated by changing direct current in the control winding. These reactors are costly but can be remotely controlled.

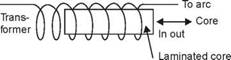

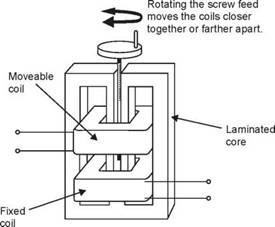

Moving coils. Changing the position of one coil along the core changes the magnetic coupling between primary and secondary. See Fig. 3.10.

Moving shunt-core. Movement of a shunt core in or out (instead of moving coils) changes the magnetic coupling between primary and secondary, and thus the welding current is controlled. See Fig. 3.11.

All these designs provide good control of current and a suitable output for MMA and GTA Welding. The choice depends upon cost and individual preferences.

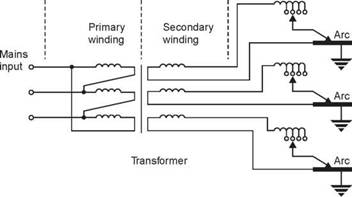

Multi-operator sets are available where one transformer provides 3 or 6 outlets. In this case, the current in each secondary circuit should be independently controlled and a separate reactor must be included in each lead. See. Fig. 3.12.

Control

current

|

|

|

Saturable reactor |

|

Transformer |

+U

|

|

|

Auxiliary transformer |

|

Fig. 3.9 Saturable reactor used to regulate welding current |

|

current flowing in this winding determines magnitude of current supplied to the arc. |

|

Fig. 3.10 Moving-coil transformer |

Core moved in or out to raise or lower current

Fig. 3.11 Moveable-core transformer

|

Tapped reactors

Fig. 3.12 Multi-operator transformer unit |

3.3. 2 Direct-Current Welding Power Sources

Direct current welding power sources could be:

— generators

— rectifiers

Generators. Motor driven generators are commonly used for welding with d. c., specially when the work is to be carried out at site. They are also preferable if the line voltage is quite fluctuating.

A generator consists of an armature rotating in a magnetic field produced by coils which are connected in series and in parallel with the armature winding.

Generator output is regulated by regulating the current flowing in the series and shunt windings. The armature must rotate at a constant speed, by using an electric motor (if mains supply is available) or by a governed petrol or diesel engine.

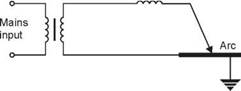

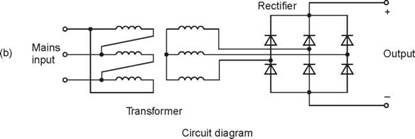

Rectifiers. A full-wave rectifier is used to convert the a. c. output from a transformer into d. c. for welding. If the input to the transformer is from single phase 50 Hz, the d. c. has a pronounced 100 Hz ripple and for most of the applications some form of smoothing is required. A three-phase input is usually preferred as it gives more uniform load on the mains supply and smoothens the ripples, eliminating the smoothening circuit (Figs. 3.13 (a) and 3.13 (6)).

For MIG welding the transformer winding is tapped so that the output voltage can be selected to suit the arc length. Since there is no requirement for current control, the unit consists simply of a transformer and a rectifier.

|

(a) |

|

Mains- |

|

► Rectifier |

|

-► Output |

|

► Transformer |

|

Block diagram

Fig. 3.13 Simple three-phase full-wave rectifier unit for welding |

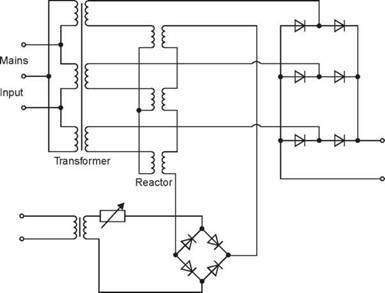

In case of manual metal arc and GTA welding a reactor is introduced into the a. c. line between the transformer and the rectifier to obtain drooping volt-ampere characteristics (Fig. 3.14). The reactor behaves in a similar way as in a. c. welding supply units. Saturable reactors are commonly used in most of the units because they are better suited to three-phase operation and can be remotely controlled. It is important to note that a reactor controls (opposes)

a. c. only. In d. c. circuit it has no effect on steady flow of current: but it opposes any changes in current level, which is a good feature for low current GMA Welding.

|

|

|

Output to arc |

|

Fig. 3.14 Drooping characteristic output from rectifier unit |

By providing extra taps to the output from the reactor in a transformer reactor set, it is possible to produce a combined a. c./d. c. unit suitable for MMA and GTA welding. This type of

power unit is more useful when there is a mixed type of requirement in a job-shop, but it costs more than individual a. c. or d. c. unit.

Опубликовано в

Опубликовано в