Junction temperature and peak emission wavelength

15 марта, 2014

15 марта, 2014  admin

admin |

Subsequent to the calibration, the peak emission energy is measured as a function of the DC |

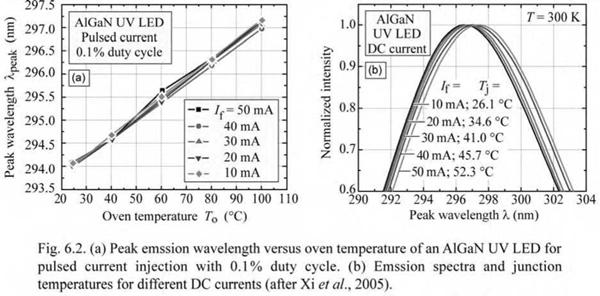

This method makes use of the dependence of the bandgap energy (and thus the peak emission wavelength) on temperature. The method consists of a calibration measurement and a junction- temperature measurement. In the calibration measurement, the peak energy is measured at different ambient temperatures, typically in the range 20 °C to 120 °C, by placing the device in a temperature-controlled oven. The device is injected with a range of pulsed currents with a duty cycle << 1 to minimize additional heating. As a consequence, the ambient temperature in the oven and the junction temperature can be assumed to be identical. The calibration measurement establishes the junction-temperature versus emission-peak-energy relation for a range of currents. Calibration data for a deep UV LED are shown in Fig. 6.2 (a) (Xi et al., 2004; 2005).

|

|

injection current with the device in a room-temperature ambient. The junction temperature for each current level can then be determined by using the calibration data. Figure 6.2 (b) shows the emission spectra of the UV LED for different injection currents. The junction temperatures inferred from the calibration measurement are shown in Fig. 6.3 (Xi et al., 2005).

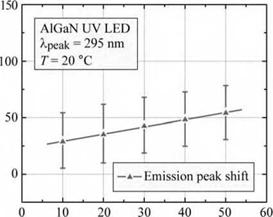

The accuracy of the method is limited by the ability to determine the peak wavelength. As a rule of thumb, the error bar of the peak wavelength is about 5-10% of the full-width at halfmaximum of the luminescence line. Alloy-broadening effects and kT broadening impose a limitation on the accuracy of the method.

|

|

|

DC forward current /j - (mA) |

|

Fig. 6.3. Junction temperature inferred from emission peak energy as a function of DC injection current for a 300 pm x 300 pm deep UV LED emitting at 295 nm. The error bar stems from an uncertainty in the peak energy (after Xi et al., 2005). |

The shift of the emission energy with respect to temperature (d£g / dT) is due to the temperature dependence of the energy gap. The change of the energy gap can be calculated from the Varshni parameters to be discussed in the subsequent section of this chapter.

Note that band-filling effects should not influence the results as they also enter the calibration measurement. The peak emission energy shifts to higher energies due to band filling occurring at high injection current densities. In contrast, the peak emission energy shifts to lower energies due to bandgap shrinkage. Although it is difficult to clearly separate the junction- temperature-induced shift from the band-filling-induced shift, the former effect dominates under typical experimental conditions.

Опубликовано в

Опубликовано в