Metal Inert Gas (MIG) Welding

17 марта, 2014

17 марта, 2014  Oleg Maloletnikov

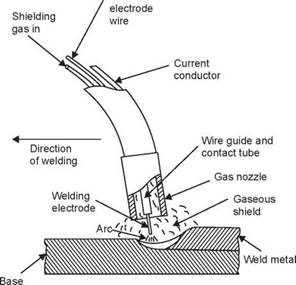

Oleg Maloletnikov In MIG welding the arc is maintained between a consumable electrode and the workpiece in inert gas medium. It is used as a heat source which melts the electrode and thus supplies the filler metal to the joint. The principle of operation is shown in Fig. 2.7. The apparatus consists of a coil of consumable electrode wire, a pair of feed rolls, a welding torch having a control switch and an inert gas supply. Consumable wire picks up current while it passes through a copper guide tube.

|

Solid

metal Fig. 2.7 Metal Inert Gas (MIG) Welding |

• Electrode wire diameter is between 1 .5 mm to 3.0 mm and current used is between 100 to 300 A for welding aluminium, copper, nickel and alloy steels (current density is of the order of 100A per mm square: thus projected transfer occurs). The arc projects in line with the wire axis and metal also transfers in the same line.

• Projected transfer occurs within a range of current. Below the lower limit the transfer is gravitational and above the upper limit, for aluminium, the metal flow is unstable resulting in the formation of dross, porosity and irregular weld profile.

• Welding may be done below the threshold current and conditions could be adjusted to get short-circuit transfer. Wires of 0.75 mm diameter or less with wire reel directly mounted on the gun itself could be used with short circuit or dip transfer. Such a welding is called fine-wire welding and is suitable for joining sheet metals.

• Dcrp is commonly used and a power source with flat characteristics is preferred for both projected and short circuiting transfer, as it gives more consistent arc-length.

Welding of aluminium is only possible with dcsp. Drooping characteristic power sources may also be used with a choke incorporated in the circuit to limit the short circuit current and prevent spatter.

• Shielding gas is normally argon, but argon-oxygen mixtures (oxygen: 20%) are sometimes used for welding austenitic stainless steels in order to impove weld profile. Similarly 80% Ar + 20% CO2 improves weld profile of carbon steel and sheet metal and is cheaper and better than pure argon. CO2 shielding can also be used.

• The process is suitable for welding high alloy steels, aluminium, copper, nickel and their alloys. it is complementary to TIG, being particularly suited to thicker sections and fillet welds.

• MIG spot welding gives deeper penetration and is specially suitable for thick materials and for the welding of carbon, low alloy and high alloy steels.

Опубликовано в

Опубликовано в